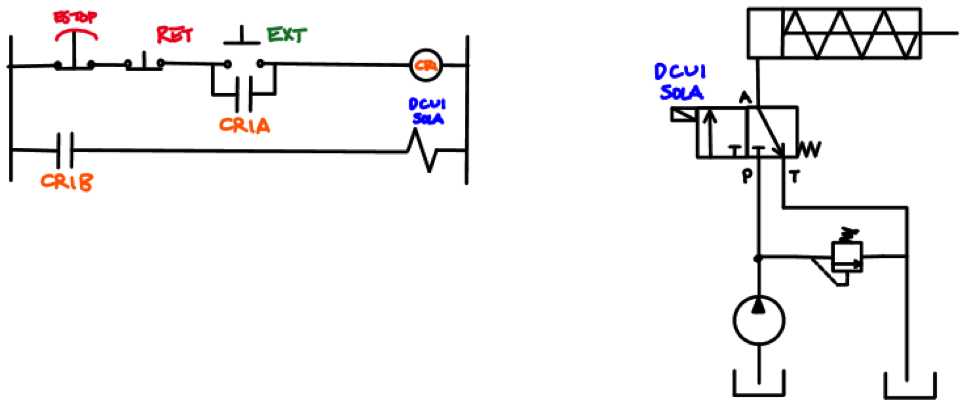

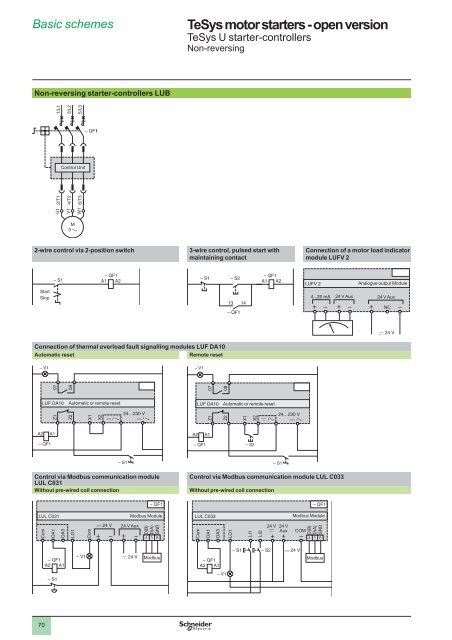

In both circuits shown above the reverse command can be ignored if not necessary for the application still the same circuit is applicable for 2 wire and 3 wire control. 2 wire rtds are mostly used with short lead wires or where close accuracy is not required.

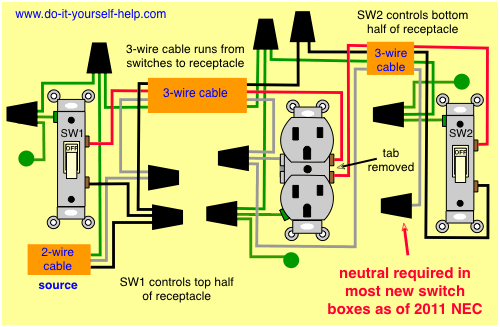

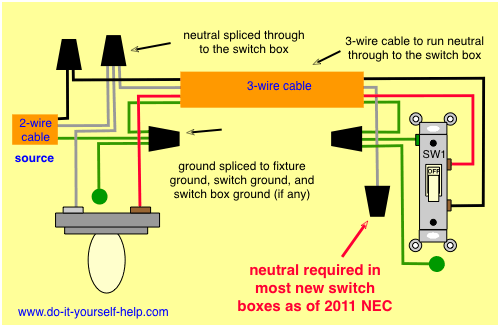

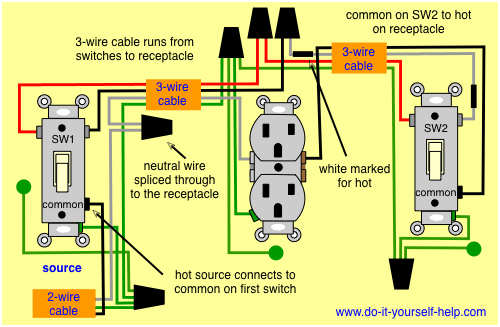

Light Switch Wiring Diagrams Do It Yourself Help Com

2 wire vs 3 wire control. The 3 wire system is less common than the 2 wire system it includes a neutral at the switch as well as the live and switched live wires. The two wire circuit in configuration 2 operates as follows. It means if the stop command is provided separately it is called 3 wire control and if separate stop command is not provided separately it is called as 2 wire control. 2 wire construction is the least accurate of the 3 types since there is no way of eliminating the lead wire resistance from the sensor measurement. If the single pole switch marked s1 is left open then the liquid level switch in the circuit will now be the control. If the single pole switch is toggle closed the motor starter will start and stay on for as long as the single pole.

One example of a 3 wire lighting system. 2 wire circuit a 2 wire black and white with the ground cable will be used for one hot and one neutral or one circuit. A 3 wire pump actually has four wires going into the control box and 4 wires going to your pump. An example of a 3 wire lighting circuit is shown in figure 2. Ironically a 2 wire pump actually has three wires coming from your home to the pump two hot and one ground. 3 wire circuit a 3 wire circuit black red white and the ground cable can be used for feeding two circuits that will share the neutral and ground wire.

When to use 2 wire control and when to use 3 wire control. In h2os experience we find the 2 wire pumps to be more reliable and robust. 2 wire control vs 3 wire control. What is the difference between 2 wire rtd 3 wire rtd. Benefits of a 2 wire over a 3 wire pump. Below is a control box.

2 wire control and 3 wire control. Inside is the relay and start capacitor.