Continue reading for the full comparison. It is ideal for temperature ranges of 40f to 250f.

Customized Silicone Epdm Fkm Viton Buna N Rubber Oring

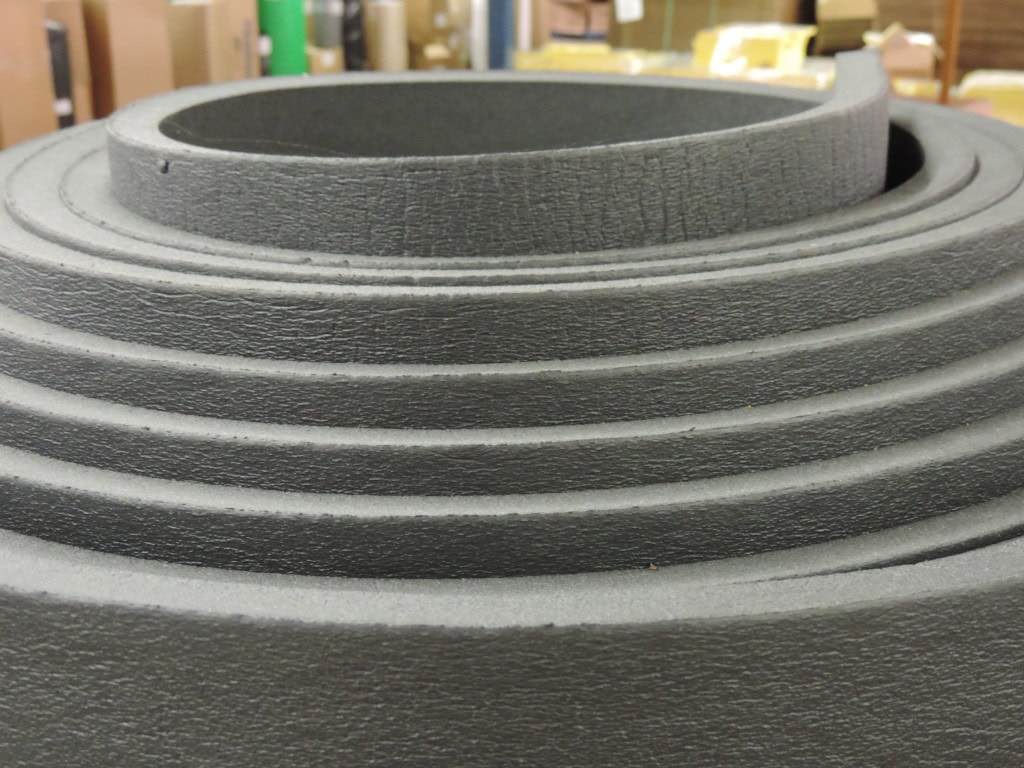

Buna n vs epdm. We offer three different premium gasket materials for our steel storage tanks. Buna n nbr nitrile. Epdm ethylene propylene diene monomer is a specially designed synthetic rubber for water applications. Meanwhile buna is only effective in the same manner up to 250f and is the better option for low temperature seals as low as 30f. Selecting the proper gasket material can make a significant difference in the lifespan of the tank. Epdm rubber is used in applications that demand both flexibility and ruggedness.

Epdm several factors must be considered. Nbr is compatible with petroleum fluids including dinosaur and synthetic lubricating oils pure gasoline and diesel fuel. Which seal for your application. Buna n b rated for temperatures 0f to 180f. Viton is the choice over buna for high temperature applications. Epdm which stands for ethylene propylene diene monomer has its own set of properties that make it an extremely popular o ring material.

Temperature tolerance chemical compatibility and cost. About us success stories contact us. Page 1 of 2. Excellent ozone chemical and aging resistance. Epdm is not resistant to hydrocarbon solvents and oils chlorinated hydrocarbons turpentine or any other petroleum based oils. Rubber properties neoprene epdm buna n silicone sbr butyl natural rubber gu.

Viton seals hold indefinitely at temperatures up to 400f and can last up to 48 hours at temperatures up to 600f. Animal and vegetable oils ozone strong and oxidizing chemicals. Rubber compounding is a very broad and technical field since basic rubbers or elastomers are mixed with various chemicals and. Made from odorless and tasteless compounds it can be wisely used in both specialty and general purpose applications. When comparing viton vs. Epdm viton or buna n.

Nitrile butadiene 30 f 250 f. The major weakness of epdm rubber washers and other seals is that they break down and deliver poor sealing performance in systems handling petroleum based fuels oils and solvents. Buna n sometimes shortened to just buna is a trade name for nitrile rubber known internationally as nbr. Poor resistance to petroleum based fluids. Mineral oils and solvents aromatic hydrocarbons. Ethylene propylene 40 f 300 f.

Buna n is also commonly identified as nbr nitrile or hycar. As a sealing option the crucial difference between buna and viton is the temperature range the materials function in. Rubber properties the chart below is intended to help in the material selection stage of designing rubber parts products. Buna which is also known as nitrile buna n perbunan or nbr performs well in applications requiring metal adhesion and abrasion resistance. It is normally the least expensive of the rubber types we will discuss here. Nitrile rubber nitrile rubber also known as buna n is made by combining the polymers butadiene and acrylonitrile.