You will learn how to measure the drive. This video briefly discusses how to measure pinion angle operating angle of the driveshaft from the transfer case and some other common issues.

Driveshaft Angles Why They Matter And How Keep Them In Check

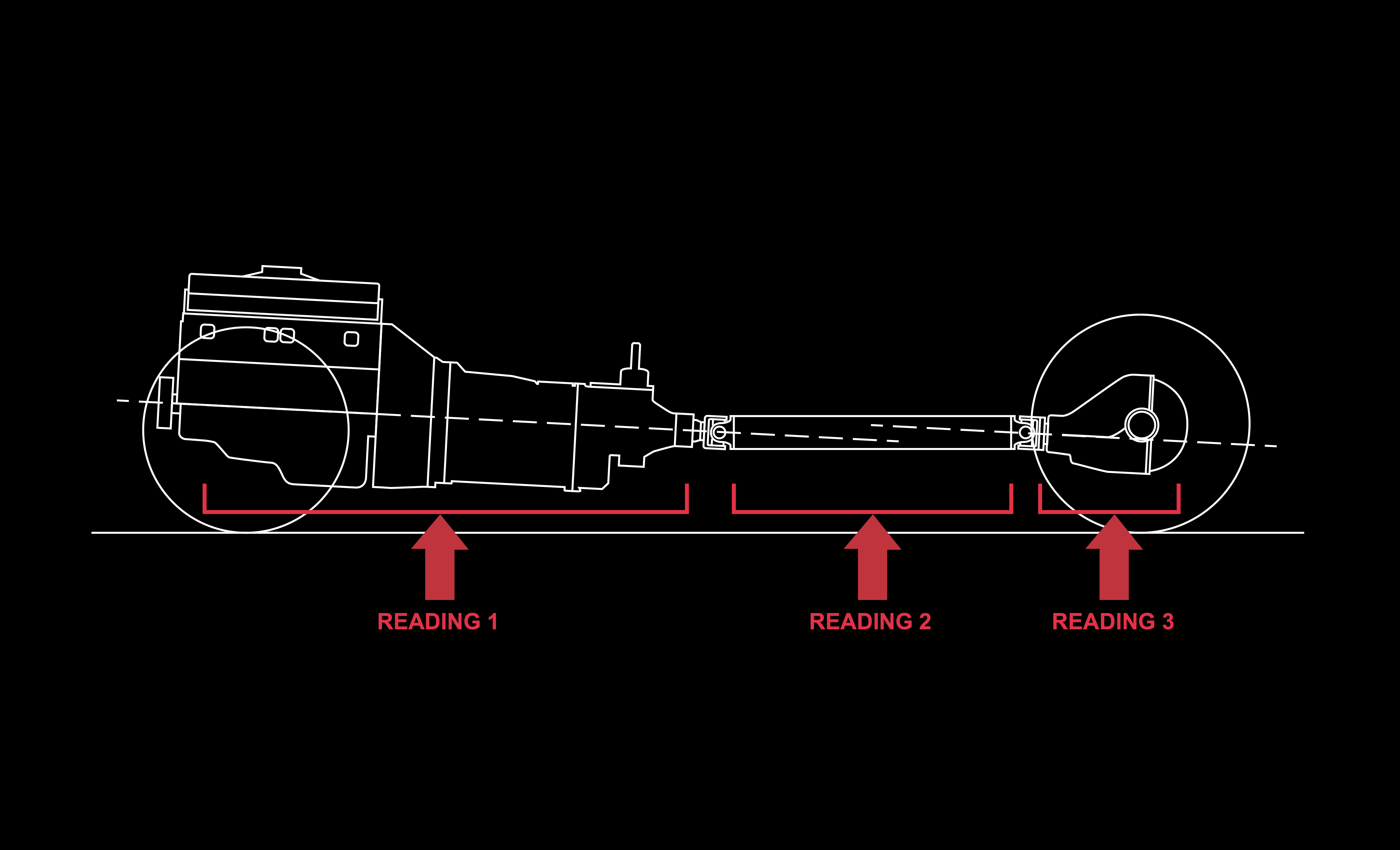

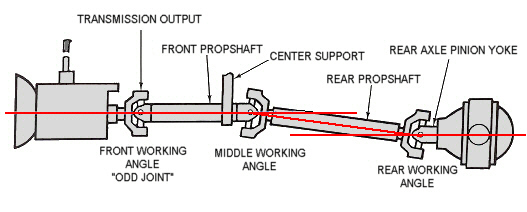

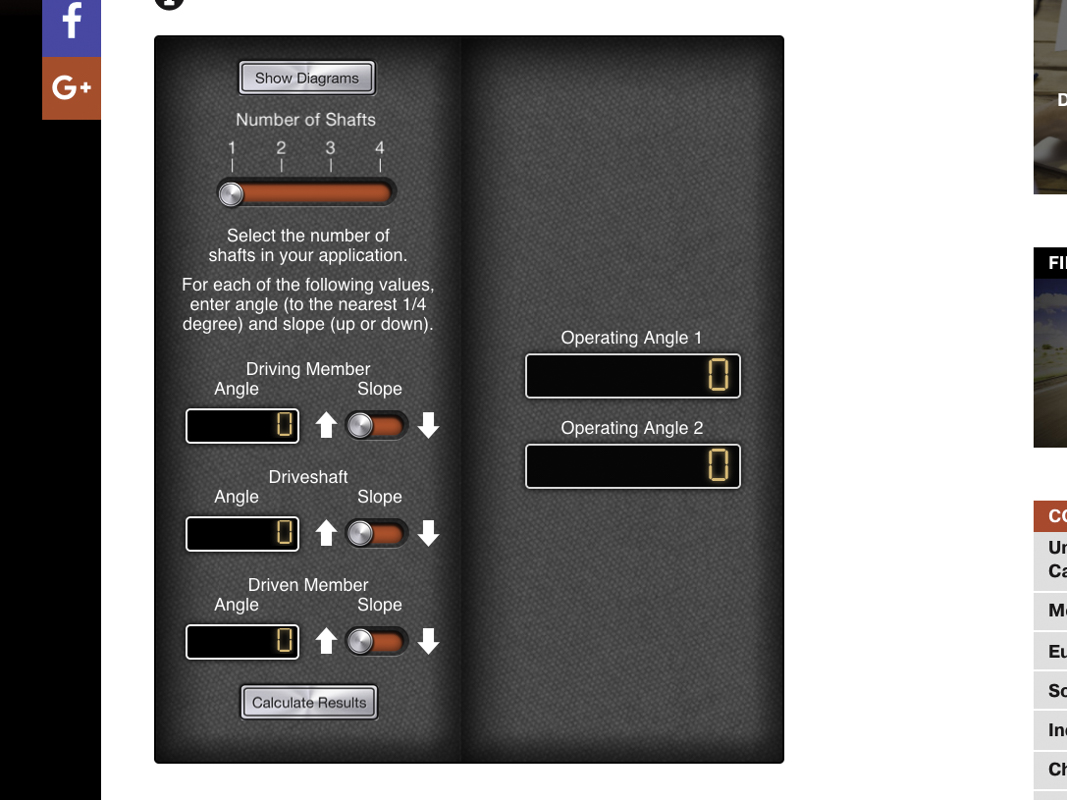

Drive shaft angle video. This video offers a quick tutorial that can makes measuring driveline angles a snap. Place an angle finder on the bearing cap and take note of the reading. What you hear are the changes in speed as the driveshaft rotates in an elliptical pattern rather than spherical and this causes a vibration in the seats mirrors gearshift. The spicer website also includes a chart of values for vibration free performance showing driveshaft rpm vs operating angle when the operating angles exceed the 3 12 degree limit. Rotate the driveshaft 90 and repeat step one. Clarence barnes explains the important role that the angle of the drive line plays in transferring torque from the transmission to the rear differential.

Find the difference between the two readings and this will be that u joints working angle. Torque converter how does it work. A couple of simple rules should be followed to help prevent driveshaft vibration. This is an example of an analogue angle measure that can be used but only when a digital meter is not available. Driveshaft angle trainer duration. You can see and hear what happens as the angles change at the u joints.

One of the most common causes of driveshaft vibration is universal joint operating angles. This youtube video demonstrates in the best high school shop class way how driveline angles work. This video shows how the different angles of the output shaft universal joints and input shafts have a dramatic effect on the balance of the driveline. How the velocity of your drive shaft changes and may cause vibration. Driveline set up diagnosis and repair is an easy process but it is often misunderstood.