It shows the percentage of leakage and pinpoints the part causing the compression leak. The abn cylinder leak detector around 31 comes with 12mm and 14mm fittings and must be calibrated before each use by manipulating the schrader valve for the regulator.

How To Do Compression And Leak Down Tests The Aftermarket

Engine cylinder leak down tester. A compression test is a dynamic test engine moving a cylinder leakdown test is a static test engine at rest. 47 out of 5 stars 11. In contrast to the cylinder leak down test which measures how much pressure is lost in the engine. Pressurized air is supplied to each cylinder and in moments displays a rate of leakage measure from 0 to 100. In a cylinder leak down test the engine is placed on tdc of the cylinder in question. This cylinder leak down tester gauges leak down tests more accurately than standard compression tests.

Today its common practice to use a cylinder leakdown gauge to evaluate how well each cylinder performs in retaining pressure. Leak down is the percentage of compression that is lost by the engine and every engine has some. Like a compression test a leak down test is accomplished by replacing a spark plug with the tester hose. Get it as soon as tue jul 14. The maddox cylinder leak down tester is designed to provide one of the most accurate tests available for diagnosing overall engine health. So the compression test measures how much pressure the engine can produce while cranking.

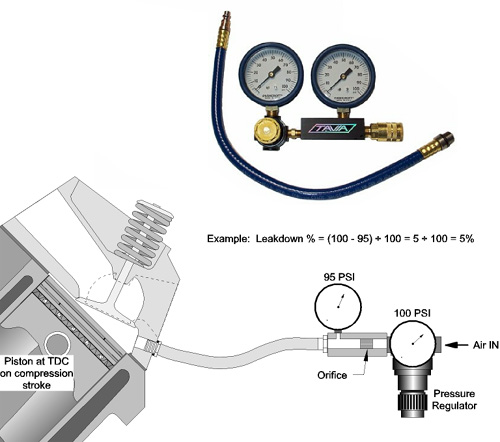

Instead of measuring the engines ability to create pressure compressed air is introduced into the cylinder through the spark plug hole. Performed a cylinder leakage or leak down test after a cylinder balance and a cylinder pressure test has verified a problem with the cylinder. Large easy to read gauges have a color scale for precise readings. Free shipping by amazon. It is also important to note this type of tester is not rated to measure more than 100 psi. New leak down tester tu 21 engine cylinder leak tester leakage detector engine compression tester gauges set.

Remove the spark plug and place the problem cylinder at tdc top dead center of the compression stroke. Unlike a compression test a leak down tester has two gauges and requires a compressed air source. Quick connect fittings make setup fast and easy. The process is simple enough pump a measured amount of air pressure. An engine leakdown test is a compression test in reverse.