If the compression comes up markedly. With the testing tube firmly seated on the silver adapter youre ready to attach the test gauge.

How To Do An Engine Compression Test

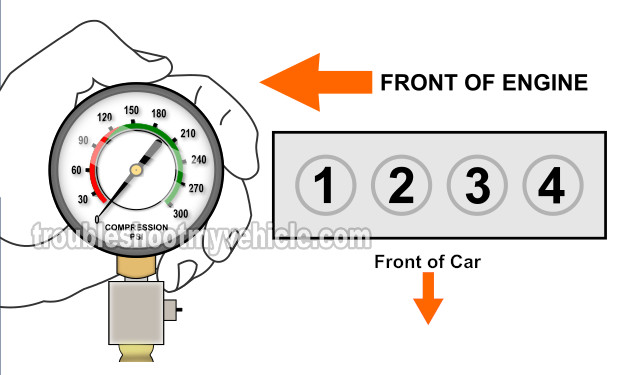

How to do a compression test. So you squirt the tablespoon of engine oil into a cylinder that is reading low. Step 1 remove the fuel pump and fuel injection fuses. The trouble is poor ring to bore sealing. Give it a tug to be sure that its on. This mixture must be placed under pressure in order for the engine to create any power. The gauge displays engine compression.

This disables the ignition system and fuel delivery system which ensures the engine does not ignite during the test. After pulling in the air and fuel during the intake stroke the piston is now forced back up in the cylinder compressing that air and fuel mixture. Crank the engine at least 4 times to. If youre testing a diesel engine make sure youre. Press the pressure release valve on the side of the gauge which will return the gauge to zero pressure for the next test. Disconnect spark plug wires.

Adding oil to spark plug hole for wet compression test. Once you have the results you compare your gauge reading to manufacturer specifications and interpret your results. Connect the compression gauge to the opposite end of the hose. With a compression tester a few hand tools and 20 minutes you can try this yourself. A compression test can also inform of an individual cylinder problem which can be repaired. Put the compression test adapter into the engines first cylinder.

Cylinder compression can inform you on how much wear an engine has on. Then retest the cylinder. Disconnect the main wire to the coil and spark plug. You can compression test the cylinders with the help of a compression gauge. Crank the engine two revolutions or so to spread the oil. This is the stroke in which you will be performing the compression test.

To complete a compression test the engine needs to be shut off. To install it pull back the collar at the end of the gauge and slide it over the metal end of the tube. You should also remove the fuel pump relay switch and the electrical connection to the coil pack. Look down on the engine to figure out which. Performing the test 1. 40 psi or more.

All you have to do is connect the gauge in place of a spark plug and test each cylinder pressure in turn.