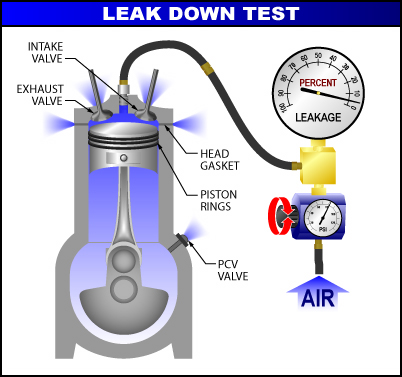

Compressed air 80 to 90 psi is then fed into the cylinder. If you prop open the throttle blades and hear that same.

Anyone Modified A Leak Down Tester For Diagnosing A Cylinder

How to make a leak down tester. How to leak down a barrel valve block off all injector lines returns except for hat nozzles connect dual gauge tester to outlet of compressor set air compressor to read 100psi on 1st gauge connect tester to inlet of barrel valve read on 2nd gauge. Put motorcycle in high gear and have a helper apply rear brake. Make a drill bit holder. This do it yourself tester is really cheap and easy to build and you really should have one in your. How to perform a motorcycle leak down test. This video is not meant to be a definitive how toalways consult a professional repair manual before starting your repairi am not.

Double flare brake lines. The crankshaft is then turned so that each piston is at top dead centre. Diy cylinder leakdown tester duration. Making a leak down tester and why i quit facebook duration. Hide a key the right way. A threaded coupling is screwed into a spark plug hole.

How to install a custom hitch adapter. Automotive cylinder leak down testerhow to build disclaimer. Bring engine to top dead center tdc. Make an engine lift plate. Remove schrader valve from compression tester hose and insert into plug hole. Frugalpreppers garage garden 1137 views.

Make a magnetic shop tray. However a leak down tester is usually a little more expensive even at the discount stores. Make a leak down test tool. Refer to your service manualfor this procedure. If you can hear a hissing sound coming from the valve cover breather hole or from the dipstick tube then the air is escaping past the rings. A cylinder leak down test requires the removal of all the spark plugs.

Make a magnitized screw driver.