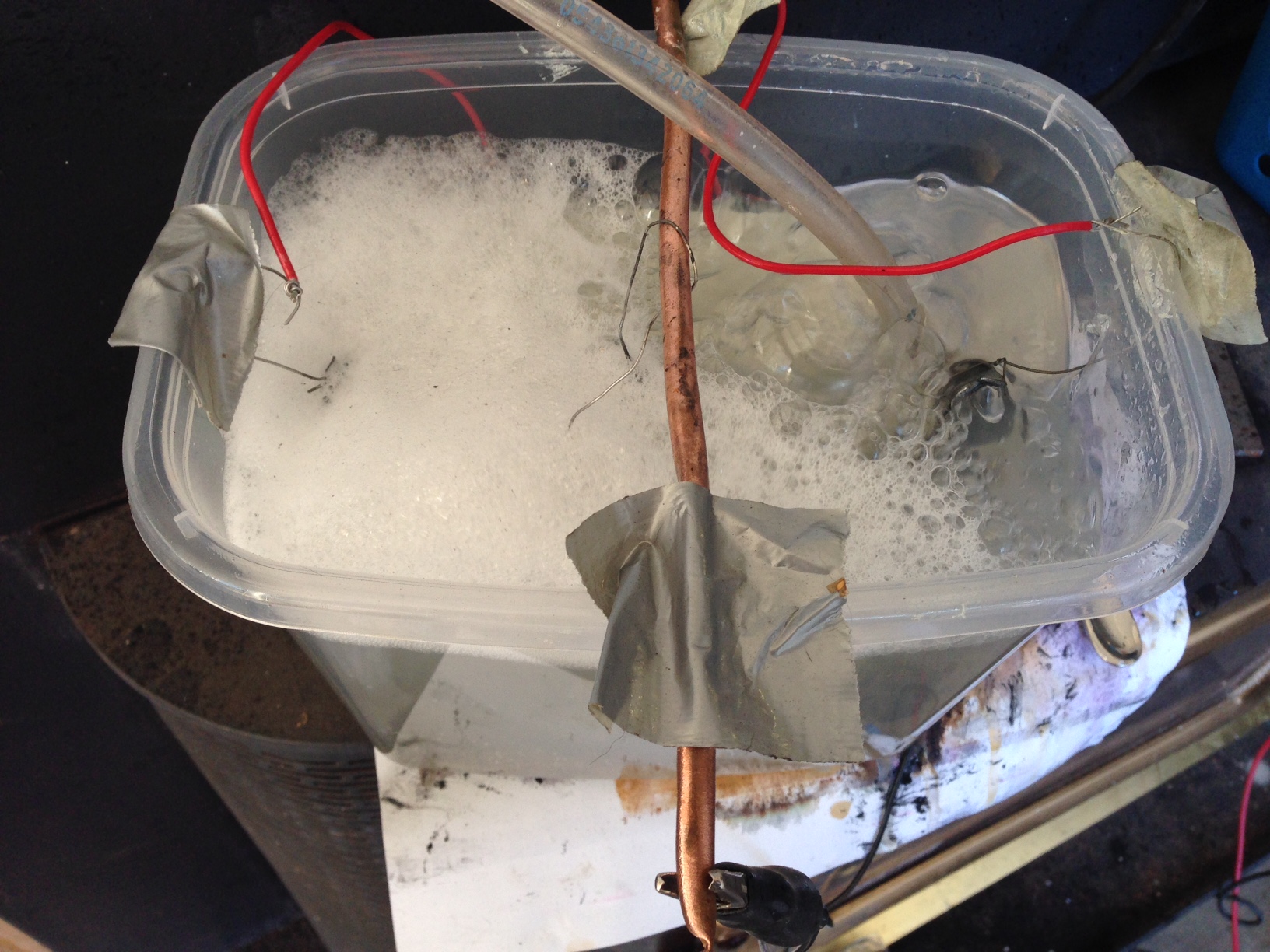

Calculate the ratio of muriatic acid to water. Following are the steps of zinc plating method at home steps 1.

Home Zinc Plating General Lh Lx Uc Gmh Torana

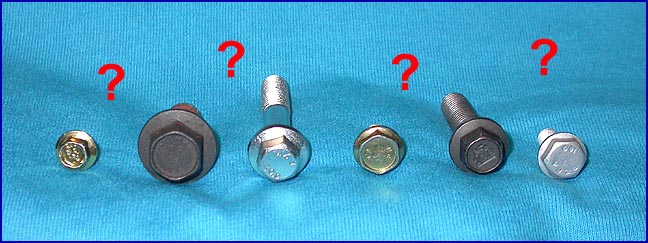

How to zinc plate bolts. Allow the zinc plating to dry for two to three hours. Yellow chromate and clear chromate which arent expensive either can be purchased from a hobby plating site like. Stud bolt with zinc nickel 12 18 ni plating plating thickness of 8 to 13μm. Add 20gm epsom salt 5. This is how i zinc plate steel parts with cheap readily available ingredients. How to strip the zinc plating from bolts.

The zinc coating creates a physical barrier that prevents rust from reaching the underlying metal surface. Add 20gm zinc granules into the solution 3. After zn ni platingwe can apply the ptfe coatingxylan 1014 coating. For a gallon solution of 110 ratio of muriatic acid to. Step 2 coat the zinc plated metal with galvanized metal etching primer using a roller and a shed free roller cover. Brush vertically applying slight pressure.

Zinc plating involves the electrodeposition of a thin coating of zinc metal onto the surface of another metal object known as a substrate. Stop and smooth the wet etching primer using a polyester paintbrush. Typical dft coating 20 25 um available in a wide range of colours. Easy way to protect metal parts from rust and corrosion by using zinc plating on those. Roll one three by three foot section at a time. Fill the container with 200ml vinegar 2.

A gallon of liquid equals 16 cups. Then the stud bolts and nuts can achieve up to 3000 hours salt spray resistance. Place all of your materials in a well ventilated area preferably outside. Here i demonstrate my diy process of garage zinc electroplating using my custom café racer motorcycle part. Put on protective.