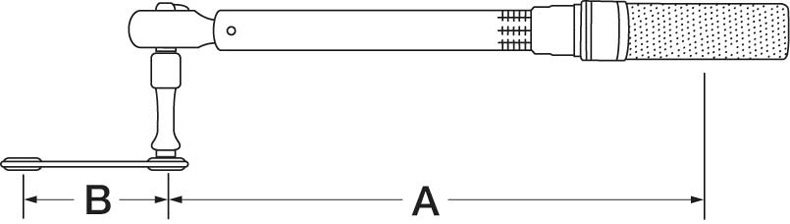

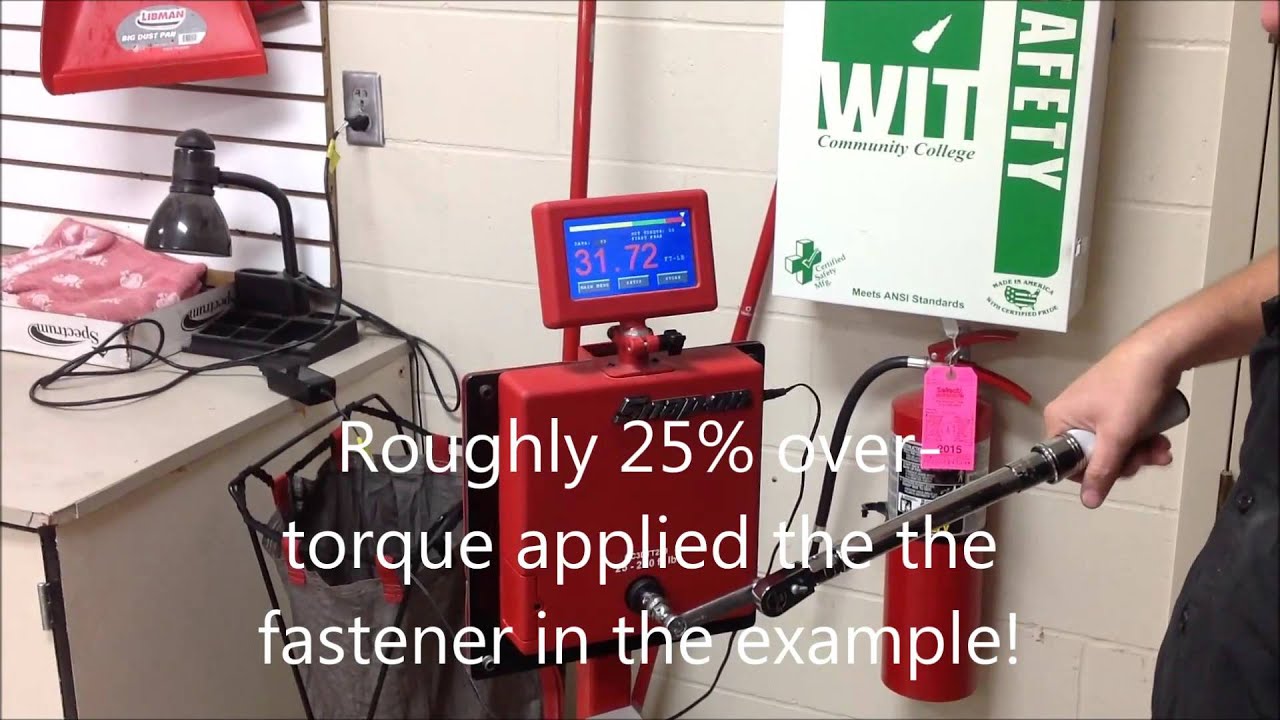

Half moon wrench left. When using extension adapters and spanners the torque applied to the fastener is greater than that preset torque setting or the torque value displayed on the tool.

Aluminum Head Right Angle Bend Extension Chuck 90 Degree Drill Attachment Adapter 8mm Hex Shank Power Electric Drill Tool

Torque wrench extension 90 degrees. To ensure that the proper torque is. 97 2257kg 10998 10998. Newer gm ls1 engines like in the camaros and corvettes use this or i wouldnt have ever heard about it. Torque wrench extension calculator. I also believe that a relatively short extension at 90 degrees will keep the torques in the ballpark. Calculations for torque wrench extension adapters and spanners.

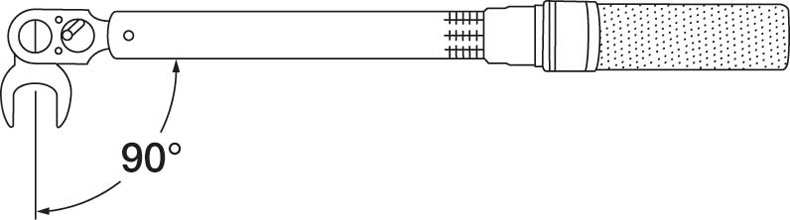

Mulwark 20pc 14 ultra low profile mini ratchet wrench close quarters screwdriver set with high torque right angle edc tool with 90 degree mini offset reversible drive handle multi hex bits set. He let the torque wrench click and then gave the wrench another 90 degrees. It does not matter how long your extension is only that it is kept at a 90 degree angle and the effective length of the torque wrench isnt changed. The rod bolts called for 35 foot pounds plus 90 degrees. Using cheater bars on torque wrenches especially click type. It doesnt matter how long the extension length is if it is turned 90 degrees to the wrench it will indicate the set value.

Nice calculator but it is irrelevant for anything other than odd angle that would never be use for a barrel or castle nut. Crows foot at 90 degrees. 15 degree wobble extension. I told him what the 90 degrees was for was for a bolt stretch guage. Reversed straight torque adapter with extension. Bulltools 12 inch drive click torque wrench set dual direction adjustable 90 tooth torque wrench with buckle10 160ftlb 10 210nm 43 out of 5 stars 47 6997 69.

I would think a longer extension or any for that matter does bring the hypotenuse into play and is evidenced by your forearm no longer being 90 degrees to the torque wrench handle. Half moon wrench right. Torque wrench with extension. If you keep it at 90 degrees to the torque wrench then your torque readings will be the same and consistent. Straight torque adapter at 90 degrees. To calculate the true torque for the fastening application use this formula.

Straight torque adapter with extension.

Gallery of Torque Wrench Extension 90 Degrees