Which seal for your application. Viton vs nitrile o rings.

O Ring Shelf Life Global O Ring And Seal

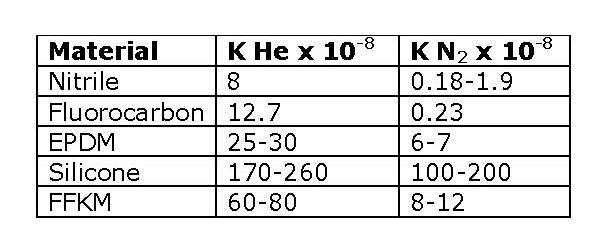

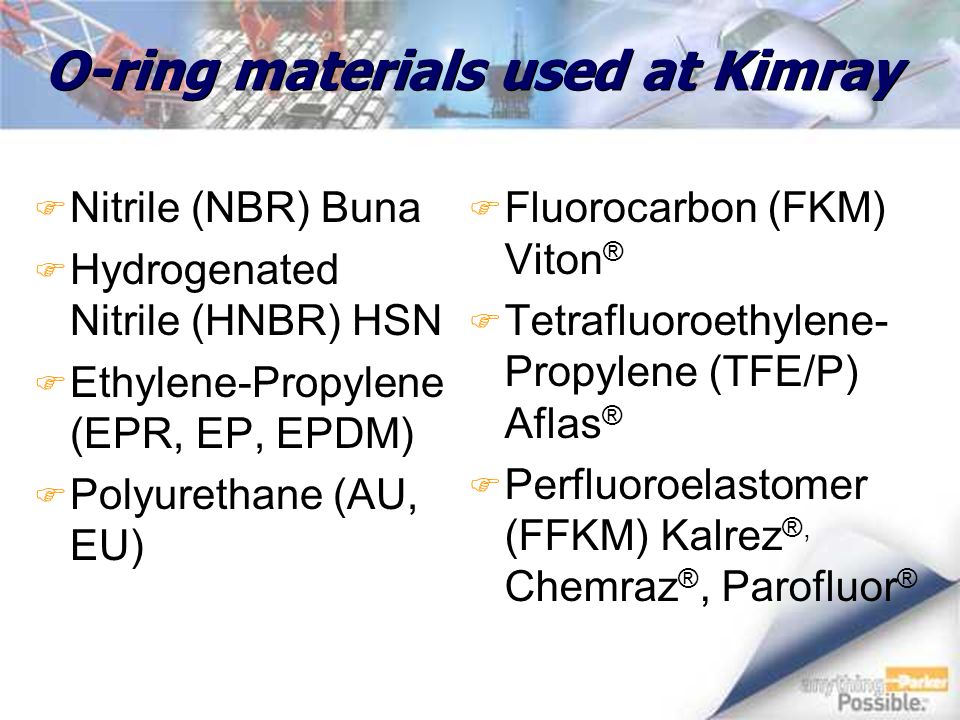

Viton o rings vs buna. Viton fluorocarbon type a. Buna n has a temperature resistance up to about 120 c. Viton seals provide an indefinite seal for temperatures up to 400f and for temperatures up to 600f they offer an excellent seal for more than 48 hours. Semicon o rings sem o rings ultra high purity seals low outgassing seals low particulate o rings. Good wear resistance good compression set resistance moderate short term resilience good permeation resistance. Viton seals hold indefinitely at temperatures up to 400f and can last up to 48 hours at temperatures up to 600f.

Viton has a temperature resistance up to about 300 c. Viton has high temperature resistance and chemical resistance. O rings made of viton are perfect for scuba diving automobile engines and valves of all kinds. As two of the most commonly used elastomers both viton and nitrile o rings have some fantastic properties. When it comes to chemical resistance viton cant be beat. 70f to 275f.

Buna on the other hand is only effective up to 250f. While both viton and buna seals both serve as great sealing options at moderate temperatures viton is far superior to buna for high temperature applications. 35f to 250f specialty. Unlike epdm viton is compatible with oils fuels lubricants and most mineral acids. As a sealing option the crucial difference between buna and viton is the temperature range the materials function in. Viton is the choice over buna for high temperature applications.

Buna n is oil and solvent resistant. For example viton over buna is essential for high temperature applications which provides an indefinite seal up to 400f and about a 2 day seal for temperatures up to 600f. Vinylidene fluoride hexafluoropropylene and tetrafluoroethylene are used to manufacture viton. Best fkm family chemical resistance known as viton etp viton extreme and super viton improved base amines ketones mtbe mek mibk resistance v1090 fkm viton glt fluorocarbon. Viton and buna seals have several very crucial differences that make them especially well suited to certain applications. Both offer excellent compression set and have a wide range of uses in industrial and domestic applications.

Meanwhile buna is only effective in the same manner up to 250f and is the better option for low temperature seals as low as 30f. Buna n nitrile order o rings online. It resists corrosion from a greater variety of fluids and chemicals than any non fluorinated elastomer.