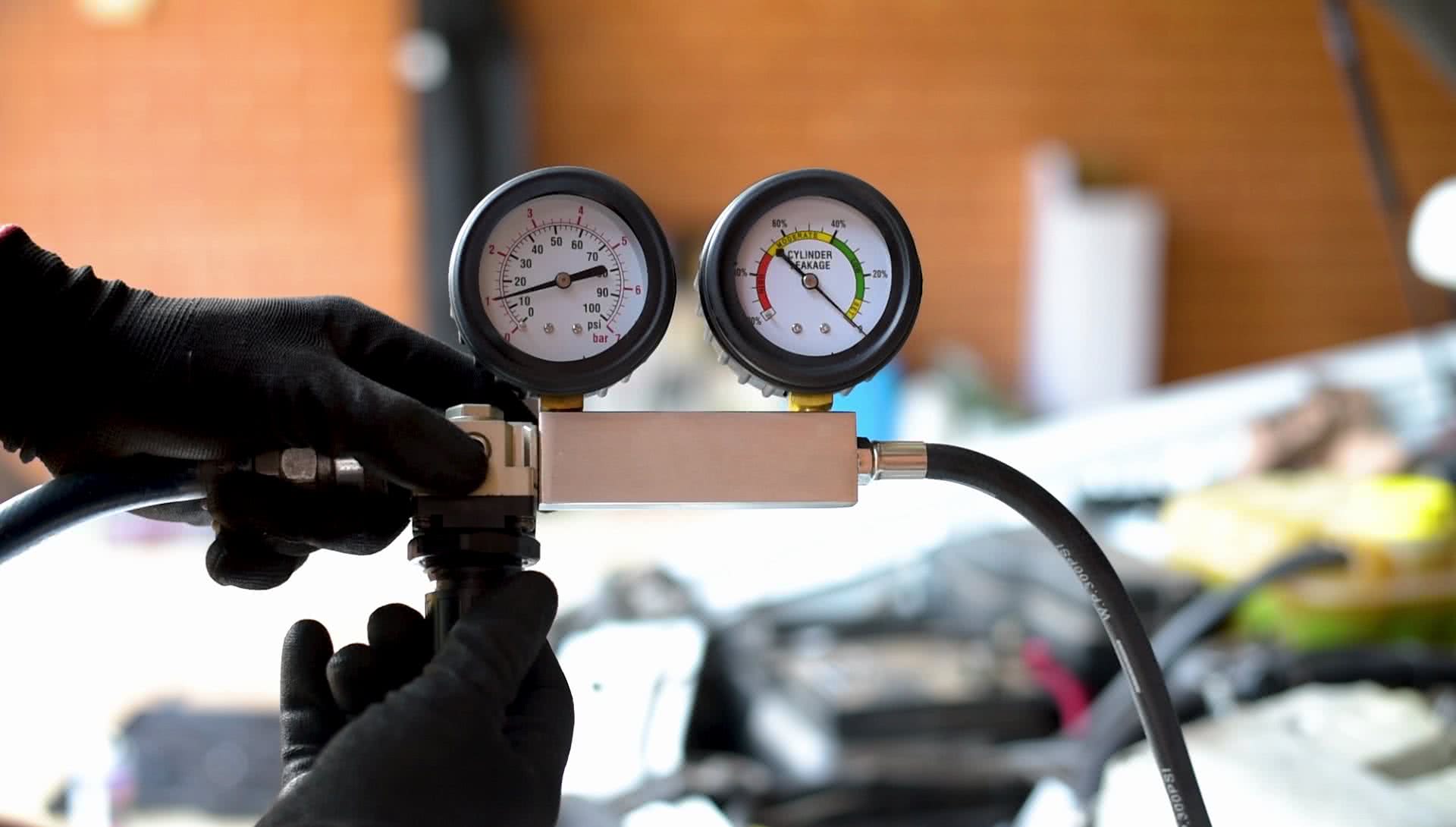

Consequently good cylinder leakdown readings should be below 5 8. This is a tool that has a hand pump.

What S The Difference Between Compression And Leak Down Testing

Leak down test head gasket. How to check for a blown head gasket step 1. These leaks are commonly seen in your spark plugs so. With the engine cold remove the oil filler cap to inspect for brown milky goo that has. Testing for a blown head gasket 1. You can listen and look for the source of where the air is exiting. Air bubbles in engine coolant seen at the radiator filler cap could mean air escaping into the coolant past the head gasket.

Head gasket leak. The tester then measures the volume of air needed to maintain a predetermined pressure in the cylinder. The cylinder leak down test reading is expressed in a percentage. The spark plug test leaks are a manifestation of a bad gasket. The seal prevents coolant from leaking out of the cylinders and it also prevents oil from leaking into the cylinders and mixing with the coolant. This is similar to the leak down test.

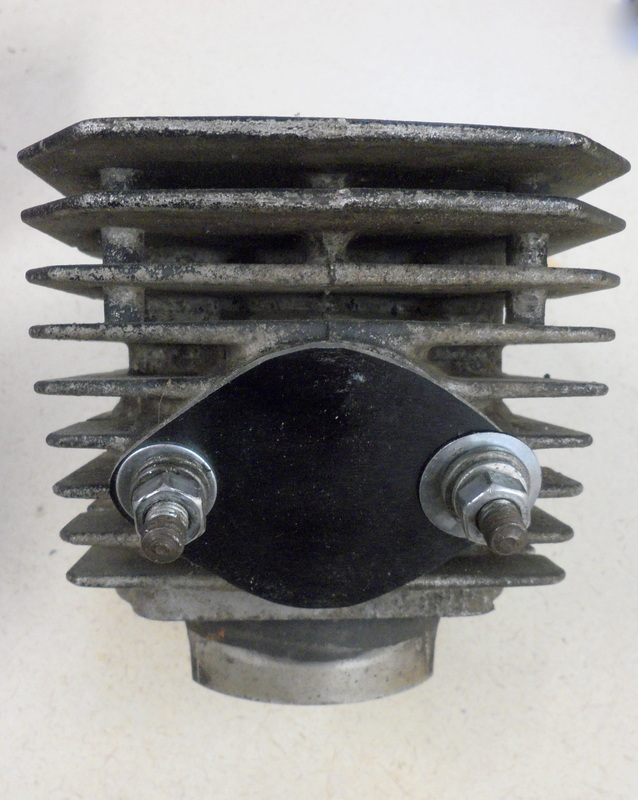

A leak down test will tell you where youre losing your compression. To test the coolant system do a coolant system pressure test. If you do have the radiator pressure test kit attach. In between the block and cylinder head is the cylinder head gasket. This pumps air into the cylinder and measures how much is lost. If you find low compression in 1 or more cylinders it could be an indication that youve got a head gasket leak in that cylinder.

Other signs of head gasket leaks or a blown head gasket include a sweet musty smell lots of white smoke coming from. This gasket serves as a seal for all the cylinders inside the block. First remove the oil filler cap and check if a. Remove oil fill cap. To test a head gasket blown between the cylinder and another port do a leak down test. Another way to test for a leaking head gasket is with a radiator pressure test kit.

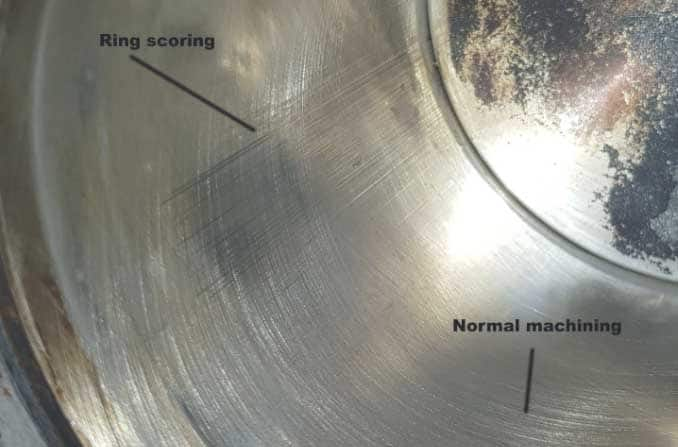

Then using a similar type of connector as the compression test we fill the cylinder with pressure. You can also try performing a compression test of your engine to find a head gasket leak. The sound of air hissing out of the oil filler dipstick tube or pcv valve indicates worn piston rings a situation informally known as blowby. Blown head gaskets will present as either air bubbles in the coolant or a hissing sound. Suspect ring or cylinder wall wear. Check for coolant in the combustion chamber.

The bubbles test when. Head gaskets are designed to control engine coolant in and around. The coffee color test for this test youd want your engine cold. If your head gasket is blown it will allow the compressed air in 1 or more cylinders to bleed off into the cooling system lowering the compression in that cylinder.

.ashx?modified=20180416133121)